Introduction to Homemade Powder Coating Machines

Homemade Powder Coating Machines are cost-effective, DIY setups designed for hobbyists and small workshops to apply durable, eco-friendly finishes on metal objects. Built using repurposed materials like modified spray guns, old ovens, and basic electrostatic components, these machines enable users to coat items such as automotive parts, tools, or furniture at a fraction of commercial system costs. While lacking the automation of industrial units, homemade versions prioritize simplicity, with budgets ranging from 50to500. Key advantages include reduced VOC emissions, reusable powder, and customization for niche projects. However, safety precautions like proper grounding and ventilation are critical to mitigate risks associated with DIY setups.

1. Components of a Homemade Powder Coating Machine

A basic Homemade Powder Coating Machine consists of:

Electrostatic Spray Gun: Modified HVLP (High Volume Low Pressure) guns or handheld units adjusted to generate 20–40 kV charge.

Powder Container: Gravity-fed hoppers or fluidized beds made from PVC pipes or metal cans.

Power Supply: Microwave oven transformers or adjustable DC power sources.

Curing Setup: Repurposed kitchen ovens, heat guns, or infrared lamps for curing at 150–200°C.

Recycling System: DIY cyclone separators or vacuum cleaners to reclaim oversprayed powder.

2. Applications of Homemade Powder Coating Machines

These Homemade Powder Coating Machines are ideal for:

DIY Projects: Coating bicycle frames, garden tools, or custom metal artwork.

Auto Restoration: Refinishing motorcycle parts, rims, or engine components.

Small Workshops: Prototyping or low-volume production of metal crafts.

They are unsuitable for large-scale industrial use but excel in scenarios demanding flexibility and low upfront investment.

3. Design Considerations for Homemade Powder Coating Machines

Homemade Powder Coating Machine Critical design factors include:

Safety: Proper grounding to prevent electric shocks; fire-resistant materials for curing units.

Ventilation: Install fans or exhaust systems to avoid inhaling powder particles.

Material Compatibility: Use conductive metals for spray guns and non-flammable insulation.

Voltage Control: Limit electrostatic charge to 30–50 kV to balance efficiency and safety.

Following homemade powder coating safety guidelines minimizes hazards in DIY environments.

4. How to Choose a Homemade Powder Coating Machine

Evaluate:

Budget: Pre-built DIY kits cost 200–500; fully custom builds may cost under $100.

Skill Level: Beginners should opt for simplified designs with pre-assembled components.

Project Scale: Smaller hoppers (1–5 kg) suit hobbyists; larger setups require advanced fabrication.

Safety Features: Prioritize systems with circuit breakers, insulated handles, and temperature controls.

5. Homemade Powder Coating Machine Q&A

Q: Are Homemade Powder Coating Machines as durable as commercial systems?

A: No, but regular homemade powder coating machine maintenance extends their lifespan.

Q: Can I use any powder type?

A: Thermoplastic powders work best; avoid materials requiring ultra-high curing temperatures.

Q: What’s the average cost savings?

A: DIY setups reduce homemade powder coating machine costs by 70–90% compared to industrial units.

Q: How to prevent powder clumping?

A: Store powder in airtight containers and ensure proper fluidization in the hopper.

Q: Is specialized training needed?

A: Basic electrical and fabrication skills suffice, but review homemade coating safety tutorials before use.

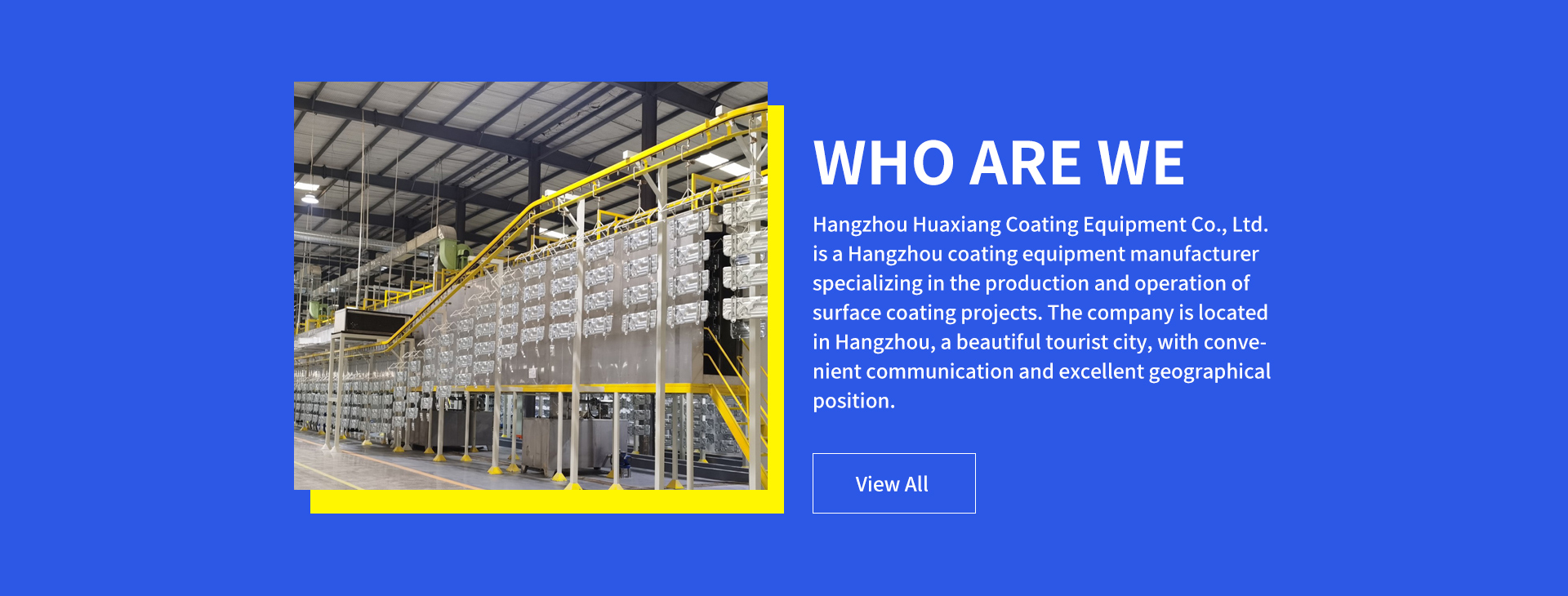

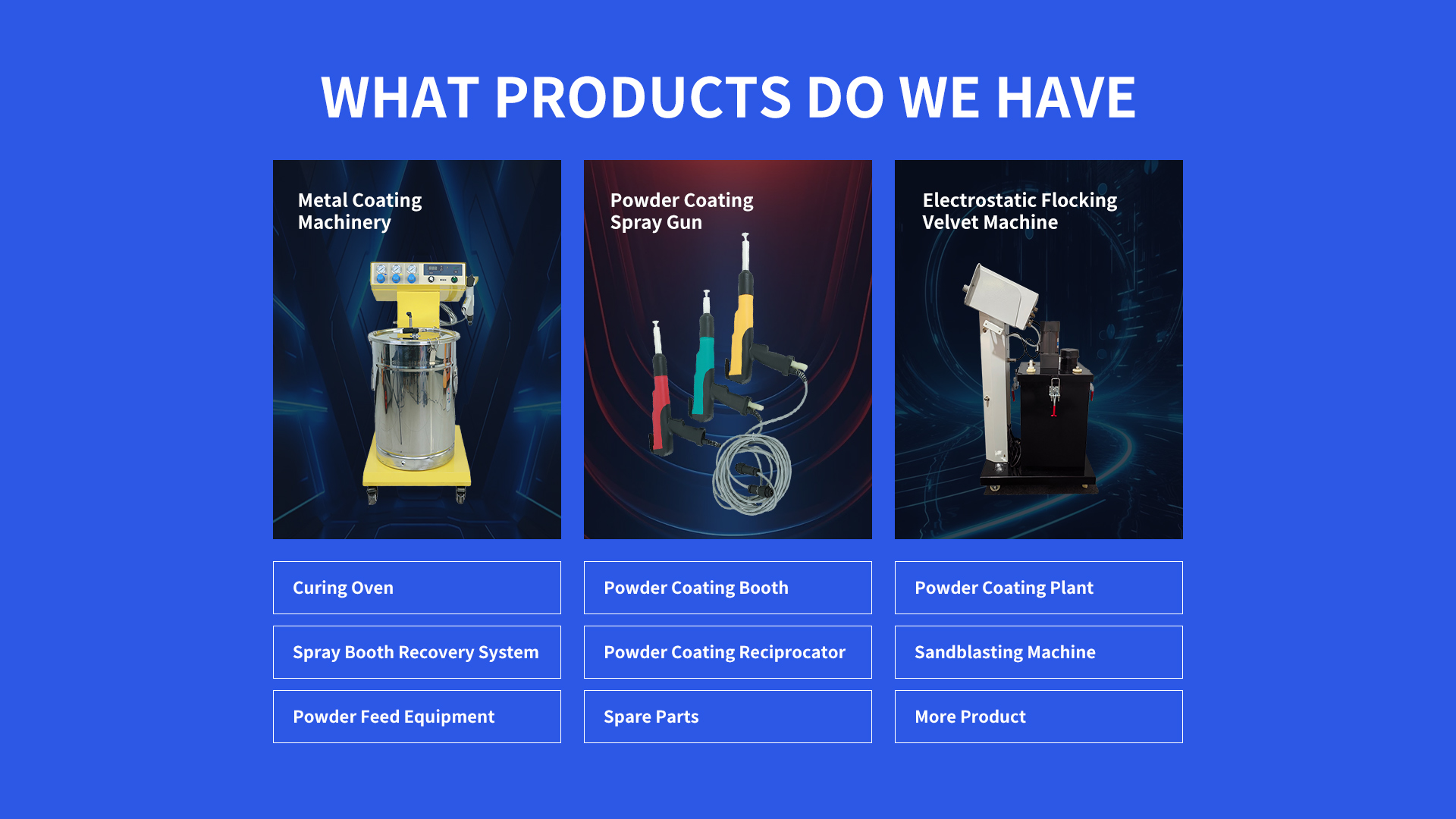

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com